Shoe Manufacturing Process: What Is Shoe Lasting and Shoe Lasting Machine?

In the modern footwear industry, efficiency and consistent quality have become increasingly important, which is why shoe lasting machines have become a popular option, overcoming the limitations of traditional manual lasting.

In the modern footwear industry, efficiency and consistent quality have become increasingly important, which is why shoe lasting machines have become a popular option, overcoming the limitations of traditional manual lasting.

In this article, we’ll talk about what shoe lasting is and how a shoe lasting machine helps streamline the process, taking the industry to the next level.

What Is the Upper of a Shoe?

The upper is the main component of a shoe, consisting of everything above the sole. It is the outer section that wraps around your foot, covering the front, the sides, and the top. The design and materials of the upper play an important role in comfort, support, and breathability.

What Is Shoe Lasting?

Shoe lasting is an essential step in the shoe manufacturing process. During this stage, the upper and other materials are pulled and shaped over a last, which is a foot-shaped mold used to create the correct size and form of the shoe. The materials are then secured with tacking or cementing so the structure becomes firm and smooth.

Shoe lasting is an essential step in the shoe manufacturing process. During this stage, the upper and other materials are pulled and shaped over a last, which is a foot-shaped mold used to create the correct size and form of the shoe. The materials are then secured with tacking or cementing so the structure becomes firm and smooth.

A well-executed lasting process improves the shoe’s stability, fit, and overall appearance. In the past, lasting work relied heavily on skilled manual labor. As production needs increased and quality standards became more consistent, lasting machines gradually became an important part of the industry, helping manufacturers achieve higher efficiency and uniform quality.

What Is a Shoe Lasting Machine?

A shoe lasting machine is a specialized device that automates the process of pulling, tightening, and shaping the upper over the last. It reduces manual labor requirements while improving production efficiency and ensuring consistent quality.

A shoe lasting machine is a specialized device that automates the process of pulling, tightening, and shaping the upper over the last. It reduces manual labor requirements while improving production efficiency and ensuring consistent quality.

Main Components of A Shoe Lasting Machine

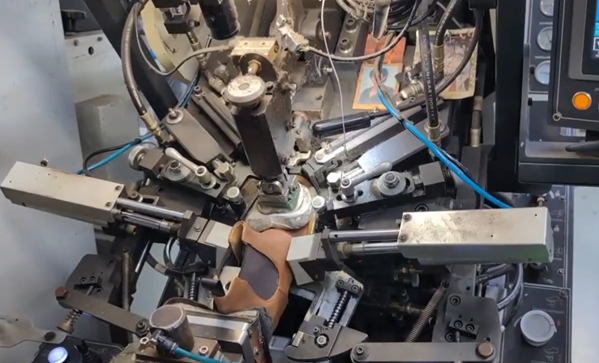

The core structure of a shoe lasting machine can be divided into five major sections.

-

Lasting Plate & Claws

The lasting plate is equipped with multiple independently controlled claws that grip the edge of the upper and pull it downward or backward. This creates uniform tension and proper alignment to the last, making it the key mechanism in the lasting process.

-

Cementing System

The cementing system applies adhesive evenly as the upper is stretched, helping it bond firmly to the insole or welt. The amount and coverage of adhesive can be adjusted based on different upper materials and production requirements.

-

Pressing Head & Banding Device

The pressing head secures the shoe last in place to stabilize the operation, while the banding device helps press the stretched upper onto the bottom, eliminating wrinkles and improving shaping quality.

-

Control System

Most lasting machines use a PLC control system with a touchscreen interface. It allows operators to store and adjust parameters such as tension, stroke, and pressing time. This enables quick changeovers between different shoe styles and ensures consistent quality across different shoe designs.

-

Power System

The machine is powered by hydraulic or electric systems that provide stable pulling and pressing forces, helping maintain accuracy and efficiency throughout the lasting process.

How Does a Shoe Lasting Machine Work

The shoe lasting process follows a series of automated steps to shape the upper and bond it securely to the last. PLC and servo systems control the claws, adhesive application, and pressing devices throughout, ensuring consistent precision and quality.

The shoe lasting process follows a series of automated steps to shape the upper and bond it securely to the last. PLC and servo systems control the claws, adhesive application, and pressing devices throughout, ensuring consistent precision and quality.

-

Upper Preparation:The operator places the pre-treated upper onto the lasting plate, where the claws grip its edges to prepare for stretching.

-

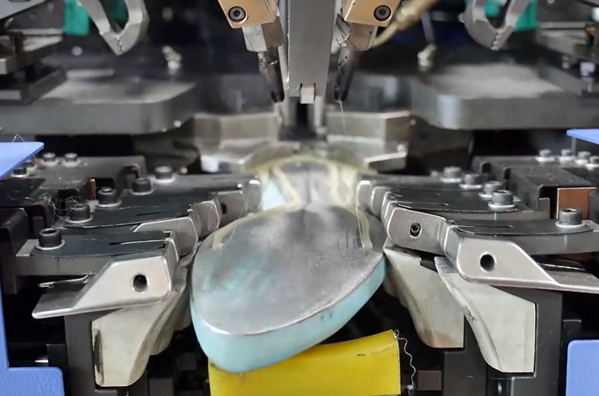

Stretching & Positioning:The claws pull the upper over the shoe last, shaping it to match the last precisely. They act like skilled hands, ensuring the material conforms evenly without wrinkles.

-

Adhesive Application & Bonding:The automatic adhesive system applies glue evenly to the insole or welt while the claws maintain tension, securing a firm bond between the upper and the shoe base.

-

Pressing & Shaping:The pressing head and banding device apply pressure to fix the upper’s shape, remove any wrinkles, and complete the lasting process.

Different Types of Shoe Lasting Machines

There are three main types of shoe lasting machines, each designed to work on a specific part of the shoe. The toe, side, and heel areas require different pulling forces and specialized mechanisms, so multiple machines are often used throughout the lasting process.

-

Toe-lasting Machines

Toe-lasting machines focus on shaping and securing the toe area. Equipped with multiple pulling claws, they stretch the upper smoothly over the toe of the last. These machines are ideal for dress shoes, athletic shoes, and any style that requires precise toe contouring.

▲ Next Generation Servo-Controlled Cement Tracer Toe-Lasting Machine (EF-889MAX)

This advanced toe lasting machine delivers servo-controlled cementing, stable hydraulic pulling, fast changeovers, and precise multi-stage pressing for premium, high-accuracy shoe shaping.

-

Heel-lasting Machines

Heel-lasting machines work on the back part of the shoe, tightening and bonding the heel area to the last. They ensure a firm heel fit without wrinkles and are commonly used for formal shoes, high-end leather shoes, and boots.

▲ New Type Automatic Hydraulic Heel-Lasting Machine (EF-861)

This automatic hydraulic heel-lasting machine delivers stable hydraulic pressure, tight heel-band attachment, adjustable wiping pressure, and high outpu

-

Heel Seat & Side Lasting Machine

Also called side-pulling machines, these work on the sidewall sections of the upper. Their main function is to pull the upper evenly along the sides of the last, which is especially important for long-vamp shoes, sneakers, and styles prone to side wrinkling.

▲ Next Generation Tracer Heel Seat & Side Lasting Machine (EF-526MAX)

This machine offers computerized cementing, precise independent pulling, and efficient heel shaping, ideal for seamless mid-heel forming in athletic and casual shoes.

Key Advantages of Shoe Lasting Machines

Shoe lasting machines offer several important benefits that improve manufacturing efficiency and product quality:

- Increased production efficiency

- High consistency & stable quality

- Reduced dependency on skilled labor

- Compatible with various materials

Learn more about advantages of shoe lasting machine: Shoe Making Insight: The Shoe Lasting Machines in Modern Footwear Manufacturing

Safety and Maintenance Tips for Shoe Lasting Machines

Proper safety and maintenance practices help ensure long-lasting performance and reliable operation of shoe lasting machines.

-

Safety Tips

-

Operator Training:Ensure operators understand the touchscreen interface to avoid errors that could damage materials or the machine.

-

Protective Measures:Wear non-slip shoes and gloves to prevent injuries from moving parts.

-

Electrical Safety:Regularly check power cables and keep the area dry to prevent short circuits.

-

Emergency Stop:Know how to use the emergency stop button and activate it immediately if any abnormality occurs.

-

-

Maintenance Guidelines

-

Maintenance GuidelinesClean the claw plate and adhesive system quarterly to remove glue and dust, keeping the machine running smoothly.

-

Hydraulic and Sensor Check:Inspect hydraulic oil monthly and clean servo sensors regularly to maintain stable pressure and accurate detection.

-

Control System Calibration:Calibrate the PLC and touchscreen every six months to ensure correct settings.

-

Lubrication and Parts Replacement:Lubricate moving components quarterly and replace worn parts, such as claws, annually.

-

Boost Your Shoe Production With the Perfect Lasting Machine

Shoe lasting machines have reshaped the footwear industry, boosting productivity, efficiency, and quality. For medium to large-scale businesses, these machines enable mass production with consistent results while offering flexibility for future growth.

Choosing the right machine and partner is crucial. YihHong is a professional manufacturer of shoe lasting machines, offering comprehensive solutions with advanced design, reliable quality, and responsive customer service. Our wide range of machines is designed to support a wide variety of production requirements.

Contact us today to discover how we can help elevate your production capabilities.